Nozzles

General

Besides creating a specific, required spray pattern with a fluid or air, a nozzle will also give a specific flow at a given pressure. It is a measuring device.

In general we distinct two main types: hydraulic nozzles (single fluid) and air mist nozzles (two fluid).

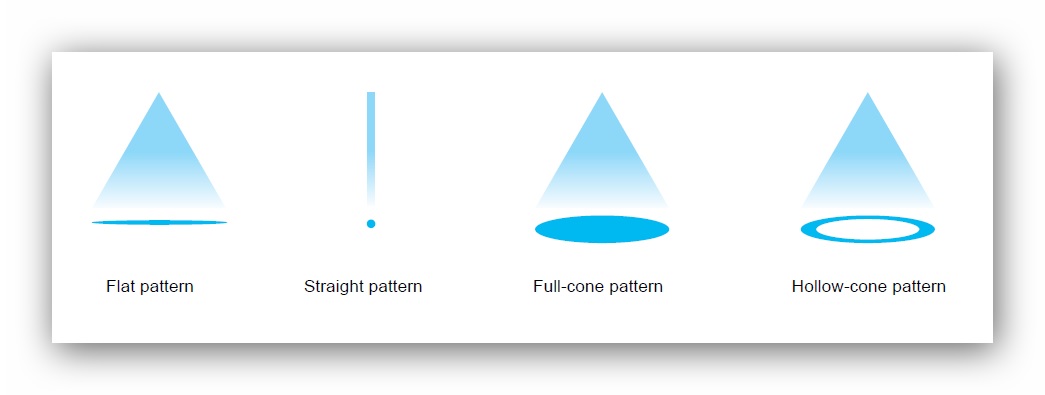

For hydraulic nozzles the following spray patterns are availble:

Spray flow rate

The relation between pressure and flow rate is ruled by the following equation:

Q1= √(P1/P2) x Q2, in which

P1 =new pressure

P2 =known pressure

Q1 = new capacity at pressure P1

Q2 = known capacity at pressure P2

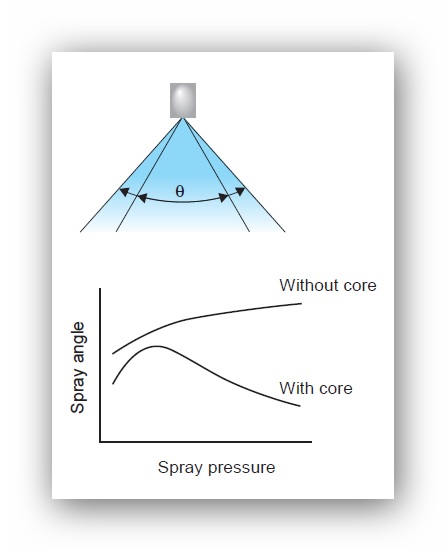

Spray angle

In general, the spray angle increases with increasing spray pressure. With some nozzles that have a core, such as a full cone nozzles, however, the spray angle increases until the spray pressure reaches a certain value and decreases thereafter with the increase in spray pressure.

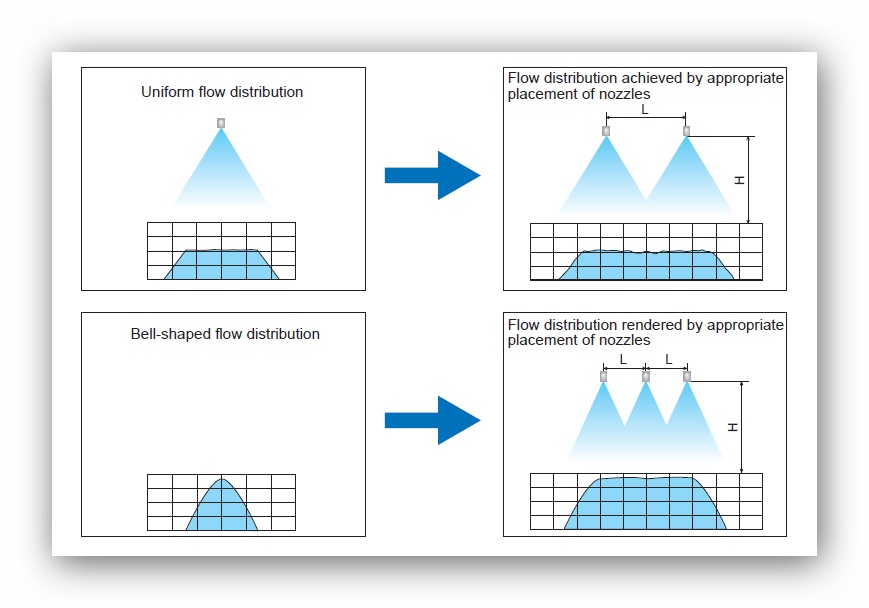

Flow distribution

For increased widthwise uniformity in spraying for single-nozzle applications, it is desirable that the nozzle renders a uniform flow distribution with minimized shoulders. In some multiple-nozzle applications, however, it is more effective for uniform flow distribution over the whole spray region if each nozzle renders a bell-shaped distribution.